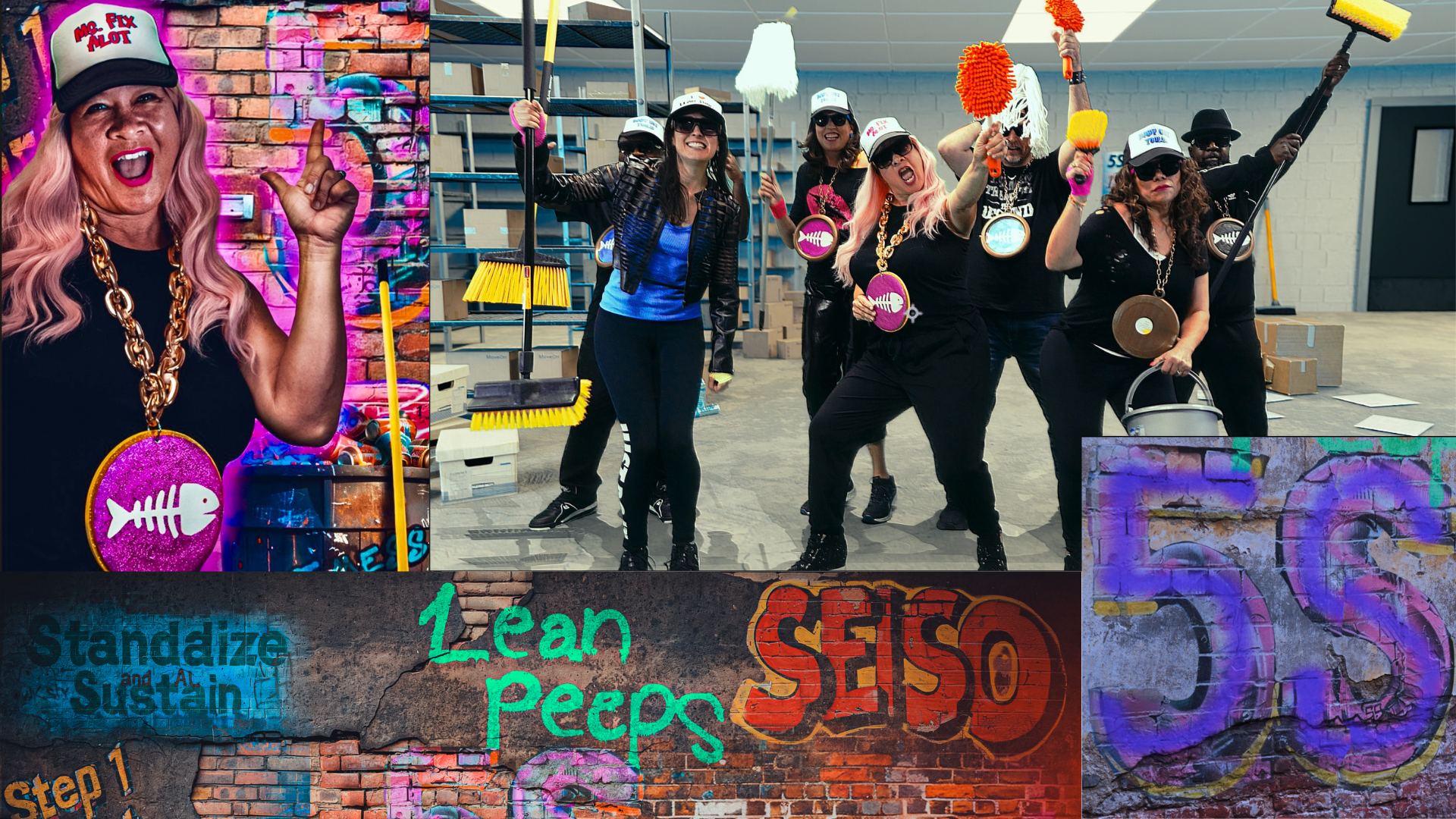

5S Workplace Organization

The 5S Workplace Organization course offers a comprehensive introduction to the principles and practices of the 5S methodology, a cornerstone of lean manufacturing and business efficiency. This course is designed to provide participants with the knowledge and tools necessary to implement and sustain 5S in their own work environments, leading to increased productivity, improved safety, and enhanced quality.

Perfect for problem-solvers, team leads, and anyone ready to stop spinning wheels with workplace organization.

5S Workplace Organization Course

The 5S Workplace Organization course offers an introduction to the purpose and

practices of the 5S methodology, a cornerstone of lean manufacturing and business

efficiency.

This course is designed to provide participants with the knowledge and tools necessary

to implement and sustain 5S in their own work environments and even at home!

Successful implementation of 5S leads to increased productivity, improved safety, and

enhanced quality of the workplace.

After this course you will:

• Understand the origin and purpose of the 5S methodology.

• Identify the five key phases of 5S: Sort, Set in Order, Shine, Standardize, and Sustain.

• Gain practical skills to implement each phase of 5S in the workplace.

• Develop strategies for maintaining and continuously improving 5S practices.

• Identify and eliminate waste, streamline processes, and enhance workplace

organization.

• Foster a culture of discipline and continuous improvement within your organization.

Course Outline:

Course Outline:

Introduction to 5S Methodology

o Origin and purpose of 5S

o The importance of workplace organization and efficiency

Sort (Seiri)

o Identifying and eliminating unnecessary items

o Strategies for effective sorting

Set in Order (Seiton)

o Organizing and arranging necessary items for ease of use

o Visual management techniques to help

Shine (Seiso)

o Cleaning and inspecting the workplace

o Establishing cleaning routines and responsibilities

o Benefits of a clean and well-maintained environment

Standardize (Seiketsu)

o Creating standard procedures and guidelines

o Implementing best practices across the organization

o Tools for documentation and training

Sustain (Shitsuke)

o Maintaining and improving 5S practices over time

o Encouraging a culture of continuous improvement

o Techniques for auditing and feedback

Conducting a 5S Event

o Conducting a 5S Event

o 5S Event Checklist

Take your career and

expertise to a new level!